Understanding Damp Proof Membranes (DPM): Protecting Your Spaces from Moisture

Damp proof membranes (DPM) are essential components in construction and renovation projects, particularly in areas susceptible to moisture. Whether you’re constructing a new building or refurbishing an existing one, understanding DPM can prevent expensive repairs later.

What is a Damp Proof Membrane?

A damp proof membrane is a barrier designed to stop moisture from passing through walls and floors. Usually made from materials like polyethylene or epoxy, these membranes are applied to surfaces to form a protective layer that prevents dampness. They are vital in environments with high humidity or where the ground contains high moisture levels.

Why Use DPM?

1. Prevent Structural Damage: Moisture can cause significant structural damage over time. DPM helps protect buildings from damp-related issues such as mould growth, rot, and corrosion.

2. Improve Indoor Air Quality: By preventing moisture ingress, DPM helps maintain better indoor air quality, reducing the risk of health issues associated with mould and mildew.

3. Enhance Energy Efficiency: Properly installed DPM can assist in maintaining temperature control within a building, thereby improving energy efficiency and reducing heating costs.

Types of Damp Proof Membranes

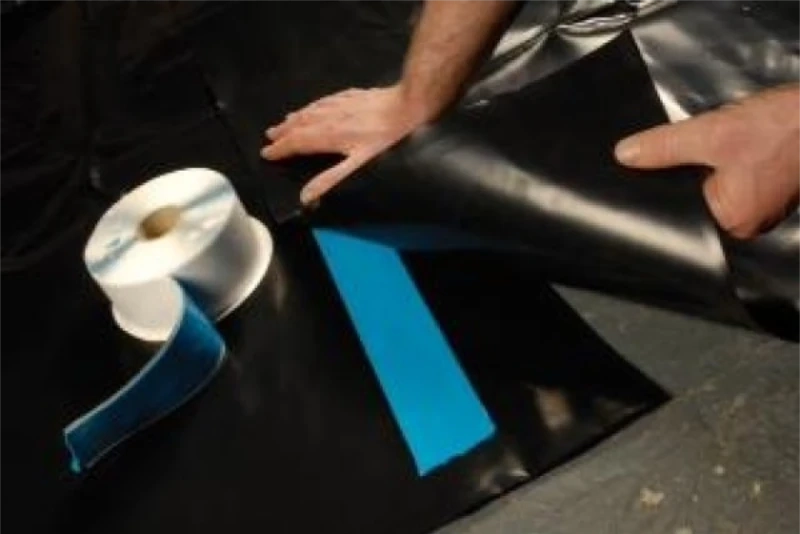

1. Plastic Sheeting: A common form of DPM, plastic sheeting is both cost-effective and simple to install. https://www.screedgiant.co.uk/product/florprotec-damp-proof-membrane/

2. Liquid Membranes: These are applied as a liquid and then cure to form a solid barrier. They can be especially effective in complex areas where traditional sheeting might be difficult to install. https://www.screedgiant.co.uk/product/ardex-dpm-1c-damp-proof-membrane/

3. Epoxy Membranes: Renowned for their durability, epoxy-based membranes are frequently utilised in high-humidity environments, offering a strong barrier against moisture. https://www.screedgiant.co.uk/product/tilemaster-adhesives-fast-one-coat-dpm/

Installation Considerations

• Surface Preparation: Make sure the substrate is clean and free from debris before applying the membrane. This helps achieve better adhesion and performance.

• Temperature and Humidity: Apply DPM in appropriate weather conditions; generally, temperatures should be above 10°C to ensure proper curing.

• Coverage Rate: The coverage rate can vary depending on the type of membrane. Always consult the manufacturer’s guidelines for the best application techniques.

Summary

To summarise, damp proof membranes play a vital role in protecting buildings from moisture-related problems. By choosing the correct type of DPM and ensuring proper installation, you can enhance the longevity of your structure and maintain a healthy indoor environment. Whether you’re a homeowner, builder, or contractor, understanding the importance of DPM is essential for successful construction and renovation projects.